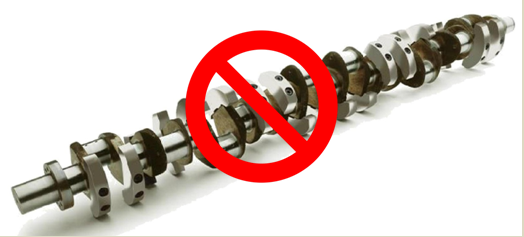

Conventional engine efficiency is ultimately

limited by crankshaft kinematics.

The internal combustion reciprocating engine (ICRE) has a high theoretical efficiency (greater than 80%). In practice, the crankshaft is cost effective at providing rotary shaft power output from an ICRE, but it causes substantial energy losses during combustion and power extraction - resulting in a cycle average brake thermal efficiency (BTE) in the range of 20 to 30%.

What is there about the crankshaft that causes such a drastic reduction in conventional ICRE efficiency? The kinematics of the crankshaft requires the combustion process to be force fit into a continually changing combustion chamber volume; which is produced by the piston reciprocation resulting from the ongoing crankshaft rotation. This distorted combustion event causes heavy energy losses for all types of combustion: SI, CI, and even HCCI. Additionally, the compression ratio (CR) of conventional ICREs is limited to modest levels by the knock properties of the fuel used, typically 8:1 to 10:1 with SI and 16:1 to 20:1 with CI. Furthermore, to maintain traditional flame front combustion, fuel/air mixtures must be excessively rich, for the available CR and associated expansion ratio (ER). i.e. Conventional ICREs require remarkable over fueling to sustain combustion.

It is well known that the ideal Otto cycle has the highest theoretical efficiency of all gas expansion engines. The key to implementing its high efficiency potential is the use of constant volume combustion (CVC) coupled with an ER higher than can be reached in a conventional ICRE. But, CVC is impossible to realize using a crankshaft! The only time the combustion chamber is not changing volume is for an instant at top dead center (TDC) - when there is a zero length moment arm. Thus, conventional flame front combustion must be timed to peak after TDC and it then continues for many crank angle degrees (CAD) after TDC. As a result, it is far from a constant volume process.

When fuel was inexpensive and there was less concern about emissions we could accept the crankshafts’ consequences. A future of ultra low emissions regulations and an inexorable global demand for fuel, with its attendant rising cost, requires better.

For the ICRE to be suitable to emerging needs and realize its full potential, we must replace the venerable crankshaft.

Fortunately, there exists a unique combination of unconventional ICRE architecture, combustion process, and operating method that can produce a 30:1 to 50:1 CR/ER. By using full load range HCCI of lean fuel/air mixtures, it can cost effectively provide greater than 60% cycle average BTE. This engine was disclosed in U.S. patent 7,258,086 (and related foreign patents). It is now designated the Otto 3GTM engine (formerly the FS-FPE).

For information about a fundamentally different ICRE please proceed by selecting:

Or for supplemental information: